Bottle Glossary

Bottle Glossary |

| Main Subject Pages |

| Home |

| Dating |

| Typing/Shapes |

|

Glassmaking ▪Makers Marks |

| Colors |

| Finishes & Closures |

| Body & Seams |

| Bases |

| Fragment ID |

|

Glossary ▪Morphology |

| References |

| Links |

| FAQ's |

| About this site |

| Website Map |

HOME: Bottle Glossary

INTRODUCTION

This glossary covers all of the specialized terminology used within this website, as well as many terms not used on this site but which may be encountered elsewhere. Some of the terminology is collector based, some is technical glassmaking jargon, some is a mixture of both, and some is of unknown origin. All pertain to and are useful for a full understanding of historic bottles. Where alternative words/phases describe the same concept, it is noted - like Bore and Orifice. When directly quoted, the source of the definition or information is noted; otherwise the references are not typically noted. This is particularly true if the definition is directly from John R. White's 1978 work on bottle nomenclature published in Historical Archaeology, since this journal article is widely accepted and referenced by historic archaeologists. (Not every term from his list is repeated on this list; only those deemed pertinent).

The terminology and definitions here are a composite of information derived

from an assortment of references, the most important of which include:

McKearin (1941), Scholes (1941), Howard (1950), Scholes (1952), Tooley (1953), Lief (1965), Kendrick (1963, 1968), Toulouse (1969a), Munsey (1970), Switzer (1974), Ketchum (1975), McKearin and

Wilson (1978), White (1978), Berge (1980), Wilson (1981), Miller & Sullivan (1981),

Jones (1986), Creswick (1987), Fike (1987 & 1998), Jones & Sullivan

(1989), Sives (1992), Whitehouse (1993), Wilson (1994), Van den Bossche

(2001), Kaiser (2009). Many other references were variably consulted also. See the References

page for more information.

BOTTLE MORPHOLOGICAL TERMS

Before the moving into the main part of the Glossary, it is useful to have a quick overview of the basic physical features - or morphology - of a typical bottle. A somewhat stylized, "typical" bottle is illustrated on the following page: General Bottle Morphology. Most of the "parts" of a bottle are easier to visualize than describe. Bottle physical characteristic definitions are included on the General Bottle Morphology page as well as below in green below.

GLOSSARY

Click on the pictures to enlarge and on the hyperlinks - where available - for more information and/or a picture or illustration elsewhere within this website. Names in bold italics are specifically covered elsewhere on this page if a user is unsure about the meaning or definition.

ABM

- A commonly used acronym for Automatic Bottle Machine. The term is a short hand

reference to a machine-made bottle as compared to a mouth-blown BIMAL (blown

in mold, applied lip) bottle.

Air venting

(aka "mold air venting")

- Small vent holes in a bottle mold which release pressure and gases from the

mold while the bottle is being blown or expanded. Vent

holes usually leave

small glass "dots" or bumps on the body and sometimes the base of the finished bottle

which are typically

slightly smaller than a pin-head in size. Vented molds tended to

produce bottles with sharper embossing than those made in molds without

venting. See the

Bottle Body Characteristics & Mold Seams page for more information

on air venting.

Anneal

(annealing/annealed) - The gradual

reheating (sometimes) and cooling of hot glass to room temperature in

an oven or lehr (annealing oven or leer) to relieve the stresses in the glass

and make the bottle stable and less prone to breakage.

Applied color label (ACL)

- A method of labeling, lettering, or decorating a bottle by applying a

mixture of borosilicate glass and mineral or organ pigments (and other substances) with a low

melting point to a bottle through a metal screen and then baking it in a

furnace to form what can appear to be a "painted label." In

later years (mid-1950s), a thermoplastic wax medium was used and resulted

in more versatility and durability. Also referred to as applied color lettering, pyroglazing, pyro,

enameling,

baked enamel labeling, fire-fused, silk screening, painting,

painted, and printing. This style of marking bottles was

most commonly found on soda, milk, and some beer bottles made from 1933

(possibly as early as 1931) up

until today, e.g., Corona™ beer bottles (Giarde 1989; Sweeney et al. 2002;

Tutton 2003; Hoenig pers. comm. 2/2019). An example of a 1946

Mission Beverages soda bottle with an ACL is pictured to the left.

Applied color label (ACL)

- A method of labeling, lettering, or decorating a bottle by applying a

mixture of borosilicate glass and mineral or organ pigments (and other substances) with a low

melting point to a bottle through a metal screen and then baking it in a

furnace to form what can appear to be a "painted label." In

later years (mid-1950s), a thermoplastic wax medium was used and resulted

in more versatility and durability. Also referred to as applied color lettering, pyroglazing, pyro,

enameling,

baked enamel labeling, fire-fused, silk screening, painting,

painted, and printing. This style of marking bottles was

most commonly found on soda, milk, and some beer bottles made from 1933

(possibly as early as 1931) up

until today, e.g., Corona™ beer bottles (Giarde 1989; Sweeney et al. 2002;

Tutton 2003; Hoenig pers. comm. 2/2019). An example of a 1946

Mission Beverages soda bottle with an ACL is pictured to the left.

NOTE: For more information

download the following article recently published on this website:

Lockhart, Bill and Bob Brown (with contributions by Chris Weide and Russ Hoenig).

2019. The Glamorous Applied Color Labels. Historic Glass

Bottle Identification & Information Website, E-published September 2019. A

comprehensive article on the history, processes and use of ACL labeling which

began in the early 1930s. This article is available on this website at:

http://www.sha.org/bottle/pdffiles/ACLArticle2019.pdf

|

Applied Finish or Lip on an 1876-1886 (Wilson & Wilson 1968) Jesse Moore Bourbon cylinder fifth (San Francisco, CA.) exhibiting some of the typical excess glass flow just below the lower collar. |

Applied finish (or lip) - Also called a "true" applied finish or lip. Applied finishes are a category of finishes where the glass for the finish was "applied" in a separate process after the bottle was severed (wetted or cracked-off) from the blowpipe. (Click applying a string finish to view an illustration of the process of applying this glass.) After the finishing glass was applied to the severed bottle neck - often with additional re-firing to keep the finish soft and workable - it was then "tooled" to form the desired shape and dimensions. Virtually all finishes had some tooling done on them to form desired shapes - even many sheared finishes. What differentiates the applied finish from the tooled finish is the separate application of glass to the neck end; this was not done in the process that produces the tooled finish discussed below. The process of "applying" a finish usually results in some amount of excess glass "dripping" down below the bottom edge of the finish, as shown in the picture to the right. See the applied finish section of the Bottle Finishes & Closures main page for more information.

NOTE: The author of this website has prepared a summary of the mouth-blown bottle finishing methods section on the Bottle Finishes & Closures page which is available as a downloadable and printable (pdf) article entitled: "The Finishing Touch: A Primer on Mouth-blown Bottle Finishing Methods with an Emphasis on "Applied" vs. "Tooled" Finish Manufacturing."

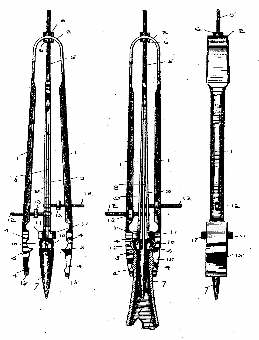

Arbogast patent

- Philip Arbogast (Pittsburgh, PA.) patented a two mold pressing and then

blowing bottle making process which was the precursor to the two mold

machine processes which facilitated the development of semi-automatic and

fully automatic bottle making machines. (Click

Philip Arbogast's

July 11, 1882 patent #260,819 to see the original patent.)

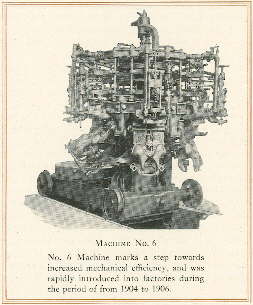

Automatic bottle machine (ABM)

- Refers to a fully automated machine that produces bottles independent of human

supplied labor, i.e., gathers the glass automatically from the furnace,

uses mechanically air pressure to the blow the bottle to shape, and

requires no hand finishing work to form or finish the lip. These bottles are also

sometimes called

Full-Automatic machine produced. The acronym "ABM" is used as a short hand reference

for all machine-made bottles - those produced by the Owens Automatic Bottle

Machine, other fully automated machines, most semi-automatic machines, and

semi-automatic machines converted to fully automatic via a

gob

feeder. The acronym ABM apparently originated from the collectors literature in the early 1960s (Tibbitts 1964).

Baffle mark (aka parison mark) - The seam left on the parison that marks the junction of the baffle plate and the blank mold on a machine-made bottle. Tooley (1953:452) defined it as the "Mark or seam on the bottle resulting from a mold joint between the blank mold and baffle plate." This line is found on the completed bottle in the form of a circle (centered to quite off-centered) on the base which may also extend onto the bottle heel. Like a suction-scar (aka "cut-off scar"), but unlike a valve mark, the baffle mark is joined by ghost seams on two opposite sides (Schulz et al. 2016:523). A particularly bold or bottle integrity affecting baffle mark was considered a manufacturing defect in machine manufacturing and a reason for reworking or adjusting the blank mold/baffle plate interfaces (Ceramic Industry 1949:8).

Baffle plate - The base plate of the

blank or parison mold

on a bottle making machine. The interface between the baffle plate and

the rest of the parison mold often results in a circular, often off-center

and incised baffle mark on machine-made bottle bases that somewhat

resembles an Owens Automatic Bottle Machine induced

suction scar (Tooley 1953; Schulz et al. 2016; empirical observations).

See the Machine-made section of the

Glassmaking & Glassmakers page for more information.

Baffle plate - The base plate of the

blank or parison mold

on a bottle making machine. The interface between the baffle plate and

the rest of the parison mold often results in a circular, often off-center

and incised baffle mark on machine-made bottle bases that somewhat

resembles an Owens Automatic Bottle Machine induced

suction scar (Tooley 1953; Schulz et al. 2016; empirical observations).

See the Machine-made section of the

Glassmaking & Glassmakers page for more information.

Bail

- That part of a toggle

closure device which is connected to the lever wire and passes over the lid holding

it in place on the bottle or jar. Also called a yoke (White 1978).

A bail is easier to define with a picture than

to describe. Click bail for a picture;

the bail is the vertical metal portion which holds the stopper

in place.

Bakelite - An early - probably the first - thermosetting plastic which made its debut in 1927 as a screw cap closure material though was first patented in 1907 (Berge 1980). This is the first plastic used for bottle closures though was also widely used thousands of other items including phonograph records, billiard balls, telephone and radio cases, and much more.

Ball neck -

A bottle/glass maker term for a relatively narrow, horizontal ring on the neck

of a bottle (Illinois Glass Co. 1906, 1920, 1926). It appears that this

feature was purely decorative in nature. A ball neck is illustrated to the

right on a 1875 to 1885 hair dye bottle which is described on the

Household (non-food) Typology page. Ball necks are most often

encountered on medicine, sauce, pickle and

flavoring extract bottles but can be found on a wide array of other style

types dating from the mid-19th to mid-20th centuries (and even today).

Bar Bottle

- A fancy, variably decorative specialty bottle intended to be re-filled and re-used indefinitely for

dispensing various types of liquor; see the image to the left. Most

bar bottles were made with colorless (clear)

glass though not exclusively; amber, emerald green, cobalt blue and other

colors have been noted by the author. A bar bottle is generally distinguished from a decanter

in that bar bottles do not have a flanged finish and are clearly

designed to receive a cork rather than a glass stopper, though there are

many exceptions to this (Ketcham 1975). See decanter

below. The bar bottle pictured to the left has a molded swirled

body and dates from around 1900. (Photo courtesy of American Bottle

Auctions.)

Bar Bottle

- A fancy, variably decorative specialty bottle intended to be re-filled and re-used indefinitely for

dispensing various types of liquor; see the image to the left. Most

bar bottles were made with colorless (clear)

glass though not exclusively; amber, emerald green, cobalt blue and other

colors have been noted by the author. A bar bottle is generally distinguished from a decanter

in that bar bottles do not have a flanged finish and are clearly

designed to receive a cork rather than a glass stopper, though there are

many exceptions to this (Ketcham 1975). See decanter

below. The bar bottle pictured to the left has a molded swirled

body and dates from around 1900. (Photo courtesy of American Bottle

Auctions.)

Barber bottles

- A class of decorative, often art glass quality bottles that were used by

barber shops and individuals to hold various hair treatments and products.

Barber bottles were intended to be refilled from other containers and reused

indefinitely. They were produced from the mid-19th century to the

1920s (Ketchum 1975). The picture to the right is of a mouth-blown,

turn-molded, blowpipe pontil scarred example from the late 19th to early

20th century. It has the original "sprinkler" type closure which is

made of metal and cork.

Barber bottles

- A class of decorative, often art glass quality bottles that were used by

barber shops and individuals to hold various hair treatments and products.

Barber bottles were intended to be refilled from other containers and reused

indefinitely. They were produced from the mid-19th century to the

1920s (Ketchum 1975). The picture to the right is of a mouth-blown,

turn-molded, blowpipe pontil scarred example from the late 19th to early

20th century. It has the original "sprinkler" type closure which is

made of metal and cork.

Bare iron pontil - see iron pontil

below.

Base - The

bottom of the bottle; the surface upon which the bottle stands. Any

measurements of the base on this website are of the greatest diameter

(round) or greatest width and depth (non-round). The "resting point"

of the bottle is usually the extreme outside edge of the base. See

General Bottle Morphology pop-up

page. Also see the

Bottle Bases page for a comprehensive overview on the subject.

Base plate

- Base forming portion of a bottle mold. See bottom plate.

Batch - A mixture of raw glassmaking materials

in the correct proportion ready for the melting

pot.

Battledore - A wooden paddle used to flatten portions of a bottle as

it is being hand blown (Hunter 1950).

Bead

- A raised ridge of glass having

a convex section which encircles the neck of a bottle. The term itself

can be applied to any such circle or molding; also a modifier indicating its

specific location, e.g., closure bead, collar bead (or beaded collar), etc. (White

1978). The term is also used to describe a raised ridge located

between the screw-threads and shoulder on many 20th century fruit jars and

which formed the sealing surface for the cap and rubber gasket. Bead is also a type of finish - click

bead finish to view a description within the Finish Types & Styles pages.

The upper closure accepting part of a crown cap finish is a bead.

Beaded seal

- A bottle that makes its seal or

point of maximum contact on a beaded ridge which encircles the bottle neck.

The ridge just below the screw threads and cap on a

Ball® Perfect Mason fruit jar is a beaded seal. The rolled top portion of a

crown top finish

could also be considered a beaded seal (see

crown top picture below).

Beveled edge

A term used in describing typically rectangular or square bottle shapes, this is a

narrow flattened edge between two wider flat, perpendicular sides of a bottle.

Click

bottle bases for a picture that includes two bottles with beveled edges: the

rectangular bottle in the middle and the square one to the right.

BIMAL

- Acronym for "Blown in Mold, Applied Lip." The term is a short hand

reference for virtually any mouth-blown bottle, as versus

ABM bottles

(Automatic Bottle Machine).

Bird swing - This is actually a

glass makers term which refers to a bottle making flaw of a thread or bridge of glass on

the inside of a bottle

running from one side to another (Ceramic Industry 1949:21). This is a function of the hot glass

sticking to itself during the parison expansion

forming a bridge across the interior of the bottle as it expanded. Click

close-up of a "bird swing" to view

such inside of a small, ball neck hair dye bottle from the 1875 to 1885 period.

This particular example (entire bottle shown above next to Ball neck)

actually formed a thin membrane or shelf of glass that adhered to three sides of

the bottle - the two wide sides and one narrow side. Sometime after the

glass cooled and hardened, much of the thin membrane broke (the right side of

the flaw) leaving a relatively thick strand still remaining which bridges

between the two wider bottle sides. In the authors experience, most bird

swings are more a thick thread of glass spanning opposite sides, though they can

vary a lot in detail. It is most commonly found in mouth-blown bottles but does

rarely show up in machine-made bottles also (Ceramic Industry 1949:21).

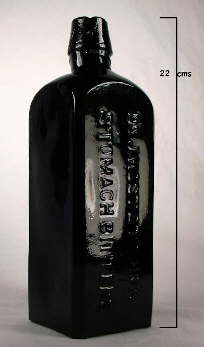

Bitters

- A class of patent or proprietary medicines, usually containing ethyl

alcohol - often in ample quantity. Bitters as a class were very popular during the

19th and early 20th centuries for the perceived medicinal qualities of the

product. The term is also used for the category of

historic bottles with the word "bitters" embossed on them. i.e., "bitters bottles."

The image to the left shows an earlier (1860s) example of what was probably

the most popular and widely distributed mid-19th century bitters

bottle - DR. J. HOSTETTER'S / STOMACH BITTERS. (See picture to the

left.)

Bitters

- A class of patent or proprietary medicines, usually containing ethyl

alcohol - often in ample quantity. Bitters as a class were very popular during the

19th and early 20th centuries for the perceived medicinal qualities of the

product. The term is also used for the category of

historic bottles with the word "bitters" embossed on them. i.e., "bitters bottles."

The image to the left shows an earlier (1860s) example of what was probably

the most popular and widely distributed mid-19th century bitters

bottle - DR. J. HOSTETTER'S / STOMACH BITTERS. (See picture to the

left.)

Black glass

- The term used to describe very dark, typically thick olive amber or olive

green (sometimes just amber) glass. Black glass usually must be held up to a

bright light to see the true color. This color was most commonly used on pre-1800 up

to the 1880s bottles used for spirits, beer, porter, ale and similar fermented

beverages though still received some use well into the 20th century on ale

and some soda bottles. See the Bottle/Glass Colors page.

The Hostetter's Stomach Bitters bottle to the left is black glass

and dates from about 1865 to 1870.

Blank mold

- See parison mold below.

Blister

- Glassmaker term for a large air bubble in the glass. See definition for

bubbles

below.

Blob or Blob-top

- The term for a relatively large class of one-part finish types that are rounded

on the outside surface and "blob-like." This finish was commonly utilized

from the mid 19th through early 20th centuries on bottles that

held carbonated beverages like soda and beer. The blob finish formed a

good anchor for wiring down the cork or stopper. The term is also used to

describe certain styles of soda a beer bottles - i.e., "blob-top soda".

For more information, click

blob finish to view the description of this finish

within the Bottle Finish Types & Styles

pages.

Blob seal - A typically

round or oval pad or disk of glass usually found on the body or shoulder (rarely

the neck or base) of a bottle which was impressed with a stamp

while hot to form lettering or designs pertinent to the bottled product

or, in earlier times (prior to the mid-19th century), the ownership of the bottle

itself (Dumbrell 1983).

Blob seals were created much like a stamp used to impress sealing wax on

a letter or document. Also called a "prunt" (Jones & Sullivan

1986) or simply a "seal" these were most common on

mid-17th through mid-19th century wine bottles, though used on a wide

variety of other bottle types. Seals were used occasionally into

the early 20th century (until at least the 1920s) on some very late mouth-blown

bottles - typically of foreign manufacture (empirical observations).

The picture to the right is of a blob seal on a mid-19th century European free-blown

"Muscat" wine bottle. Click

1727 seal to see a close-up of a dated blob seal. The term

"blob seal" likely has its origin in collector jargon.

Blob seal - A typically

round or oval pad or disk of glass usually found on the body or shoulder (rarely

the neck or base) of a bottle which was impressed with a stamp

while hot to form lettering or designs pertinent to the bottled product

or, in earlier times (prior to the mid-19th century), the ownership of the bottle

itself (Dumbrell 1983).

Blob seals were created much like a stamp used to impress sealing wax on

a letter or document. Also called a "prunt" (Jones & Sullivan

1986) or simply a "seal" these were most common on

mid-17th through mid-19th century wine bottles, though used on a wide

variety of other bottle types. Seals were used occasionally into

the early 20th century (until at least the 1920s) on some very late mouth-blown

bottles - typically of foreign manufacture (empirical observations).

The picture to the right is of a blob seal on a mid-19th century European free-blown

"Muscat" wine bottle. Click

1727 seal to see a close-up of a dated blob seal. The term

"blob seal" likely has its origin in collector jargon.

Block

- A typically wooden (usually apple or cherry, but sometimes iron) form, hollowed out on one side

for the bottle body and with a groove for the blowpipe, used in the process

of hand blowing glass to give symmetrical form to a bottle; a process called

"blocking." Bottles

produced with a block are always round in cross-section and hard to

differentiate from a purely free-blown bottle. The block was usually

kept wet with water or oil to keep the wood from igniting, to facilitate

smooth movement of the glass on the block surface (Kendrick 1968). The

marver (flat surface) was used in a similar way as a block

(hollowed out cavity) in the forming of a bottles shape without a mold or

prior to the use of a mold. A

dip mold could also be considered a type of block or block mold; see the dip mold

discussion on the

Bottle Bases page.

Block mold - Alternative name for the

parison mold on a

press-and-blow machine which

was largely a one piece "block" (Miller

& Morin 2004).

Blow-and-blow process - A

machine-made bottle forming process where the parison is blown

in both the parison mold and blow mold.

The most common automated production process or cycle used for bottles, particularly those with

narrow necks. Also see press-and-blow process.

Blow mold

- The mold within which the parison (slightly inflated gob of

glass) is expanded into the final shape of a bottle. For mouth-blown

bottles this is usually the only mold used. With semi-automatic and

fully automatic bottle machines, the blow mold is the second - and usually

final - mold used after the initial parison mold. This second

machine mold is also referred to as a "finishing mold" (Munsey 1970) or a

"forming mold" (Holscher 1953).

Blow-over

- A process (see

burst-off) as well as a mold type where the entire bottle - base, body, neck, and finish - are

formed within a mold which extends a short distance beyond the top of the

finish. Once the bottle is removed (usually burst-off) from the blowpipe and the mold, the rough glass

surface on the top of the finish is usually (but not always) ground down to

achieve a smooth surface (Jones & Sullivan 1989). Also used in

reference to "A bottle finished by grinding the mouth on a stone as

(with) fruit jars" (Bridgeton Evening News 1889). A typical item blown

in this type of mold were canning jars with either external screw threads

(e.g.,

Mason jars) or some other type of closure needing a flat sealing surface

(e.g.,

Lightning jar). The term blow-over also refers to a finish that

was made in this type of mold, i.e., a blow-over - aka burst-off

- finish. The small early 20th century English ink bottle pictured to

the left has a sharp burst-off finish and was blown in a

blow-over mold. Click

closed mold to view an illustration of a mold that would have been used

for the blow-over method. Click on the following link to see an

amazing film clip from the early 20th century showing glass blowers using

the blow-over and burst-off method of detaching the blowpipe:

Early 20th century

mouth-blown bottle making film clip.

Film clip is compliments of the

Owens-Illinois Glass Company. (Many thanks to Phil Perry, engineer with

that company.)

Blow-over

- A process (see

burst-off) as well as a mold type where the entire bottle - base, body, neck, and finish - are

formed within a mold which extends a short distance beyond the top of the

finish. Once the bottle is removed (usually burst-off) from the blowpipe and the mold, the rough glass

surface on the top of the finish is usually (but not always) ground down to

achieve a smooth surface (Jones & Sullivan 1989). Also used in

reference to "A bottle finished by grinding the mouth on a stone as

(with) fruit jars" (Bridgeton Evening News 1889). A typical item blown

in this type of mold were canning jars with either external screw threads

(e.g.,

Mason jars) or some other type of closure needing a flat sealing surface

(e.g.,

Lightning jar). The term blow-over also refers to a finish that

was made in this type of mold, i.e., a blow-over - aka burst-off

- finish. The small early 20th century English ink bottle pictured to

the left has a sharp burst-off finish and was blown in a

blow-over mold. Click

closed mold to view an illustration of a mold that would have been used

for the blow-over method. Click on the following link to see an

amazing film clip from the early 20th century showing glass blowers using

the blow-over and burst-off method of detaching the blowpipe:

Early 20th century

mouth-blown bottle making film clip.

Film clip is compliments of the

Owens-Illinois Glass Company. (Many thanks to Phil Perry, engineer with

that company.)

Blowpipe - A

long, narrow, hollow iron or steel tube used for glassblowing which was

first used in Asia Minor by the 3rd century B. C. (Hunter 1950).

The blowpipe was often referred to as just the "tube" by early glassmakers

(Hemingray 1860). Blowpipes averaged 4 to 7 feet in length, 1/2" to 1"

in diameter for most of its length (occasionally larger for larger bottles

and window glass), and were

usually tapered to a mouthpiece on

one end and slightly enlarged on the glass working end (Hunter 1950; Wilson

1994).

The glassworker blows through the mouthpiece end of the pipe to expand a

gather of

glass on the other "gathering head" end of the pipe. The gathering

head was a thicker section of ferrous alloy pipe (something resistant to

oxidation) welded onto the pipe end. Blowpipes usually had a rubber

covered section near the mouthpiece end for the glassworker to gain a better

grip for more power when turning the pipe - something that had to be done

continuously with the relatively fluid hot glass (Scholes 1952). As

noted below, the blowpipe in the early days was also frequently used as the

pontil rod.

Blowpipe - A

long, narrow, hollow iron or steel tube used for glassblowing which was

first used in Asia Minor by the 3rd century B. C. (Hunter 1950).

The blowpipe was often referred to as just the "tube" by early glassmakers

(Hemingray 1860). Blowpipes averaged 4 to 7 feet in length, 1/2" to 1"

in diameter for most of its length (occasionally larger for larger bottles

and window glass), and were

usually tapered to a mouthpiece on

one end and slightly enlarged on the glass working end (Hunter 1950; Wilson

1994).

The glassworker blows through the mouthpiece end of the pipe to expand a

gather of

glass on the other "gathering head" end of the pipe. The gathering

head was a thicker section of ferrous alloy pipe (something resistant to

oxidation) welded onto the pipe end. Blowpipes usually had a rubber

covered section near the mouthpiece end for the glassworker to gain a better

grip for more power when turning the pipe - something that had to be done

continuously with the relatively fluid hot glass (Scholes 1952). As

noted below, the blowpipe in the early days was also frequently used as the

pontil rod.

Blowpipe pontil scar or mark

- Also known as an open pontil or "tubular pontil"

(White 1978). This is a distinctive round,

sharp, and hollow "life-saver" shaped disk of glass on the base of

a bottle

which was usually formed when one end of the blowpipe itself was used for

the pontil rod. Click on

blowpipe pontil to view a picture.

Please see the

Bottle

Bases page for more information on this and the other different

types and variations of pontil scars and how to differentiate them from each

other. The image to the right above is of a blowpipe pontil on an 1840s New England

liquor flask.

Bocca - An opening in the side of the furnace through which the pot

is placed in the furnace. The glass batch is placed in the pot from which

the gather is taken. The image to the left (from a late 19th

century trade card) shows glass workers making gathers from the bocca on the

side of a glass furnace.

Bocca - An opening in the side of the furnace through which the pot

is placed in the furnace. The glass batch is placed in the pot from which

the gather is taken. The image to the left (from a late 19th

century trade card) shows glass workers making gathers from the bocca on the

side of a glass furnace.

Body

- The main content containing portion of the bottle, which lies between the shoulder and

heel

(insweep). See the

Bottle Body & Mold Seams page for much more information on bottle bodies.

Also see the

General Bottle Morphology page for an illustration.

Bottle

- As used on this website, a

bottle is a glass container that was used to contain some product or

substance. A bottle has a bore and/or neck which are significantly

smaller in diameter than the body diameter. See jar

below.

Bottle glass green

- The natural aquamarine color of bottle glass resulting from the presence

of iron oxides in the sand (White 1978). See the Bottle/Glass

Colors page.

Bottom hinge mold

- A two-piece mold that his hinged together at the bottom - base portion -

of the mold. See hinge mold.

Bottom plate

- Also know as a base plate, this is the separate mold section that formed most or all of the base of a bottle.

White (1978) defined it as "The shallow depression in the bottom of

machine-made bottles and jars designed to allow for stability..."

which is really the effect produced on a bottle by the bottom plate. Most bottle molds usually had a separate

base plate which resulted in either a

cup-bottom or post-base conformation on the resultant

bottle. Hinge molds, and the key mold variant of the

hinge mold, did not have a separate bottom or base plate. In

machine-made bottle manufacturing, the bottom plate - or simply

"plate" - is the base of the machines blow mold.

Bore

(orifice) - The opening from which the bottle contents are accessed.

Also called the aperture, orifice, opening, throat, or mouth of the bottle.

See the

Bottle Finishes page for much more information on finishes and finish parts.

Also see the

General Bottle Morphology page for an illustration.

Bubbles

- Variably sized and shaped air or gas pockets in the glass; see the image

to the right which shows hundreds of bubbles in a liquor bottle. Bubbles

is likely a collector based term, though it is quite visually descriptive

and is used on this site. Bubbles are also referred to as seeds

(small bubbles) or blisters (large bubbles) in the glassmaking industry

(Tooley 1953). The term seeds is used in reference to very

small bubbles, i.e., "seed bubbles".

Bubbles

- Variably sized and shaped air or gas pockets in the glass; see the image

to the right which shows hundreds of bubbles in a liquor bottle. Bubbles

is likely a collector based term, though it is quite visually descriptive

and is used on this site. Bubbles are also referred to as seeds

(small bubbles) or blisters (large bubbles) in the glassmaking industry

(Tooley 1953). The term seeds is used in reference to very

small bubbles, i.e., "seed bubbles".

Burst-off

- This process variation of the cracked-off finish. It is formed as follows - "Hot

glass is mouth-blown into a mould until it fills the mould. Continued

blowing results in a thin bubble of glass expanding over the mould.

This is easily burst, leaving the object with a jagged top" (Jones &

Sullivan 1989). Burst-off finished bottles were blown in a blow-over

or blow-back mold. The diagnostic characteristics that differentiate this

from the cracked-off finish are covered in the cracked-off finish

description on the

Bottle Finishes & Closures page.

Click English ink

bottle for a picture of

a late 19th century English ink with a burst-off finish. Click on the

following link to see an amazing film clip from the early 20th century

showing glass blowers using the burst-off method of detaching the blowpipe:

Early 20th century

mouth-blown bottle making film clip.

Film clip is compliments of the

Owens-Illinois Glass Company. (Many thanks to Phil Perry, engineer with

that company.)

Ca.

- Abbreviation for "circa", meaning approximately. Used on these pages

to denote an approximate age or age range, i.e., ca. 1850-1860.

Ca.

- Abbreviation for "circa", meaning approximately. Used on these pages

to denote an approximate age or age range, i.e., ca. 1850-1860.

Calabash

- A large, gourd, or pear shaped bottle (also called flasks), popular during the mid 19th century - 1850-1870.

Period bottle makers sometimes called them "globe bottles" (Wilson 1994). The name presumably originates from the

resemblance of these bottles to the hard shelled, gourd-like fruits of the

tropical American "calabash tree" - Crescentia cujete

(Gilman & Watson 1993). The image to the left is of a calabash bottle/flask

from the 1850s which is described more fully on the

Liquor/Spirits Bottles typology page.

Canning jar

- Glass jar in which food is preserved at home, typically having a wide mouth for

access and some type of (hopefully) air tight closure. Canning jars

are also largely round in cross-section, though there are some square and

multi-sided jars. Click

HERE for a picture of a typical 20th century example. Also called

a fruit jar, though canning jar is the preferred

term on this website since it is more embracing, though both terms may be

used interchangeably.

Capsule

- A lead or tinfoil (or in more recent years - plastic) secondary cover

closure used to cover the closure and finish of a bottled product.

Most familiar today on wine and champagne bottles to cover up the cork help prevent seepage and/or evaporation of the contents.

Click

capsule for a picture of one on a Ferro-China-Berner Tonic bottle

that dates from the early 20th century.

Carboy

- A much larger than usual (several quarts to 10 gallons or more) bottle which is typically

round or cylindrical and used for bulk liquid storage. Carboys were

often covered with woven wicker or enclosed in a wooden box to protect the

bottle. Also called a demijohn. See the

Carboy/Demijohn section of the "Miscellaneous Bottles" typology page.

Case bottle

- A square bottle which was designed to pack

efficiently together in a packing box or "case." A common use of this term is in

reference to square gin bottles, i.e., "case gin" - a mid-19th

century example of which is pictured to the right. Case gins are

covered in more depth at this link:

Case Gin section of the Liquor/Spirits bottle typology page.

Case bottle

- A square bottle which was designed to pack

efficiently together in a packing box or "case." A common use of this term is in

reference to square gin bottles, i.e., "case gin" - a mid-19th

century example of which is pictured to the right. Case gins are

covered in more depth at this link:

Case Gin section of the Liquor/Spirits bottle typology page.

Case wear

- Wear to the high points of the embossing, sides of a bottle, and/or the

base from the bottles contact with neighboring bottles while being

transported or otherwise handled in cases. Case wear is most common on

soda/mineral water and beer bottles which were usually re-used many times.

Click on

The Dalles Soda Works to see a Hutchinson soda bottle that exhibits

case wear on the high points of the embossing - a common location for such.

Casing (aka "plating") - The process

of encasing or layering two or more layers of colored and/or colorless

glass, to make "cased, "plated," or "flashed" glass (Wilson 1994). See

flashing.

Chair - The name for a wooden bench with

two parallel horizontal arms at which the glassblower (gaffer)

works. Kendrick's 1968 book contains excellent pictures of chairs

taken at a Mexican glass factory still using 19th century methods.

"Chair work" was a term for the bottle making hand processes done while

using the chair for mouth-blown bottle production (Kendrick 1968).

The term "chair" was also a synonym for the

shop. Click

chair use to view an illustration of a chair in use. Click

"chair" used for modern day art glass production to see a modern example

of a chair in use by a Canadian glassblower. (Photo courtesy of Bill

Lockhart) The arms of glassmakers chairs were often either of metal

(like in the linked photo) or at least covered with metal to resist the heat

of the blowpipe which was rolled on those arms.

Check - A tiny crack, usually caused

by contact of hot glass with a cold surface (Scholes 1941).

Chestnut flask

- An early American (1780-1830) free-blown and laterally compressed style of flask,

typically produced by early New England glass factories (McKearin & Wilson

1978). Click

chestnut flask for a picture.

Chill marks

- Irregular, often undulating, wrinkles or ripples on the surface of bottles

(or other glassware) usually caused by a cold metal mold or the action of a

pressing plunger (Wilson 1994), as in the case of bottles made in a

press-and-blow machine. This is particularly often seen on the neck of

press-and-blow, machine made milk bottles from the 1910 to 1940s era

(empirical observations). See the discussion about this feature on

milk bottles on the

Food Bottles & Canning Jars page.

Clapper

- Tool used in glassmaking to shape objects.

Closed

mold - A type of mouth-blown bottle

mold where the base, body, shoulder, neck, and some/all of the finish

conformation was molded - at least in part. This is as compared to an open mold

which formed the base, body, and usually (depending on the era) the shoulder and

some/all of the neck. The finish and sometimes upper portion of the

neck was not formed by the mold, but rather by the tooling of the

terminal neck glass or post-blowpipe applied glass. References

(primarily Kendrick 1963) that use these terms are somewhat confusing.

Among other questions this author is not sure if a dip-mold is considered a

primitive open mold? Whether a closed mold is a pertinent term for both

mouth-blown molds and machine molds that form most of the form of a bottle?

Also, whether a "full-size" mold (McKearin & Wilson 1978) is the same as an

open or closed mold? Generally, neither term is used on this website;

instead, the specific types of molds, finish, and other molding details are

used.

Closure

- A "device" such as a cork, stopper, lid, or cap used to seal a bottle.

See the

Bottle Closures page.

Codd stopper

- Internal closure intended for a carbonated product (usually

soda or mineral water) where the

carbonation pressure forces an enclosed glass marble against a rubber gasket

inside the bore to seal the

bottle. The illustration to the left is of the upper part of a Codd

closured soda bottle with the marble in the sealing position inside the

finish. See

Bottle Closures page.

Codd stopper

- Internal closure intended for a carbonated product (usually

soda or mineral water) where the

carbonation pressure forces an enclosed glass marble against a rubber gasket

inside the bore to seal the

bottle. The illustration to the left is of the upper part of a Codd

closured soda bottle with the marble in the sealing position inside the

finish. See

Bottle Closures page.

Collar -Used often to

denote the lower part of a two part finish, i.e., the

finish portion which lies immediately below the

lip or upper finish part (see finish

below). Some use the term collar to refer to the upper portion of a two

(or more) part finish or even to the entire finish if it is composed of only one

part (U. S. Patent Office 1875). The terms "string rim", "lower part", or ring are also used to

refer to what is called a collar here. See the

Bottle Finishes page for more information on finishes and finish parts.

Also see ring below. This is one of many variably and

confusingly used terms regarding finishes. Also see

the

General Bottle Morphology page for an illustration.

Collector jargon

- Descriptive bottle related terminology which is collector based or

originated.

Examples include "slug plate" for the typically embossed plate area of plate

mold produced bottles and the generic use of the term "applied lip" for all

non-machine-made bottles. Collector jargon will be noted where it is pertinent

to do so.

Continuous thread or screw-thread

- See screw-thread (outside) below.

Cork

- A tree bark (Quercus

suber) utilized to produce a very functional

bottle closure which is still in use today for wine and occasional other

products. In collector jargon it is a term

used for the lip or finish itself - i.e., "a cork top" bottle.

To the right is a picture of an early 20th century (ca. 1900-1910) beer

bottle with the original cork in place and the wire closure

still present.

Cork

- A tree bark (Quercus

suber) utilized to produce a very functional

bottle closure which is still in use today for wine and occasional other

products. In collector jargon it is a term

used for the lip or finish itself - i.e., "a cork top" bottle.

To the right is a picture of an early 20th century (ca. 1900-1910) beer

bottle with the original cork in place and the wire closure

still present.

Cork press

- Hand tool designed to squeeze a cork into the desired shape for use as a

closure. Click

cork press for a picture of an ornate late 19th century cork press.

Cover groove

- A groove on

top of the closure or lid that receives the bail. It keeps the closure

from slipping (White 1978). This feature is particularly common on

Lightning type fruit jars. Click

Lightning lid for a close-up picture

of the cover groove on a late 19th century Lightning fruit jar.

Cracked-off

(cracking off) - A process of removing the blowpipe from the bottle.

Cracking or wetting off entails "...scoring the glass near the blowpipe with a wet file

or other tool to create a localized thermal tension. A sharp tap on

the blowpipe detaches the glass object. The crack-off surface is flat

and uneven with sharp, often jagged edges..." (Jones & Sullivan 1989).

Cracked-off is also a type of finish; click

cracked-off finish to view the description of this finish on the Bottle

Finish Types & Style page. Click

scroll flask finish to see a picture of a cracked-off finish. Other terms for this finish include "break-off", "burst-off", and

"wetted off"; see wetting off below. Also, see the

cracking-off and shearing section of the main Bottle Finishes & Closures

page.

Crazing (aka "crazing lines") - An grouping of short fissures or

checks most commonly

found in and/or immediately adjacent to the finish (i.e., upper neck) of an

true applied finish bottle, though can also be

found rarely in some tooled finishes. It results from the heat differential

between the hot applied finishing glass and the cooler neck glass.

Click

crazing marks to view an image of a bottle neck/finish with crazing evident.

Crown top or cap - Metal cap used as a closure on primarily beer and soda bottles and still widely in use with the same dimensions as when patented in 1892. Also a type of bottle finish that takes a crown cap. The image to the left is of a crown cap finish without the cap in place. Click on Bottle Finish Types page to view the section of those pages which covers this finish type.

Cullet - Waste or recycled crushed

glass added to new glass batches - reportedly up to a quarter of the volume

- as a flux as its addition would lower the batch melting point as well as recycle a

useful product (Bridgeton Evening News 1889; New York Herald 1910; Hunter 1950). The term

apparently comes from the French word cueillette meaning a gathering,

a picked-up lot, a collection (Trowbridge 1870).

Cup-bottom (or cup-base) - This

refers to a bottle base configuration formed from a mold base plate which was shaped

like a very shallow and wide "cup" (actually more bowl shaped) and

formed the entire conformation of the bottle base. The mold types

which produced this base orientation are referred to as a cup-bottom

mold (Toulouse 1969b; Munsey 1970) or cup-base mold -

both terms are used on this website. Bottles formed with this type mold have a horizontal seam mark at or just above

and encircling the heel of the bottle and the side mold seams do not extend

around the heel onto the bottle base. Click on

early 20th century malt tonic bottle to see an example of a cup-bottom

mold produced bottle with the mold seams pointed out. Chronologically,

this type mold

was used more commonly after the post-bottom or post-base

mold, but that is variable depending on

the type of bottle. Click on

Bottle Bases

to view the section of that page that covers this subject in much more depth

including illustrations.

Cup-bottom mold (cup-base mold) - See

entry above.

Cure - A patent or proprietary medicine that claimed to eliminate one or more

diseases. The use of the word "cure" was substantially curtailed after

passage of the Pure Food and Drugs Act of 1906 and the Sherley

Amendment in 1913 dealing with fraudulent advertising claims. Thus, bottles

with the word "cure" embossed (or on the label if present) will

virtually always date prior to 1913 (Agee 1969). "Cure" or "cures" is

also a collector term for the category of bottles with the word "cure"

embossed on them.

Date line

- From White (1978) in reference to the vertical side mold seam on a

bottle and the ability to date a bottle based on the height of the seam line.

The concept dates from Grace Kendrick's 1963 book The Antique Bottle

Collector. This is a dated and misleading term as it is well understood

now that the height of the vertical side mold seam is at best a poor

indicator of the age of a bottle. Click

mold seam dating "thermometer" to view a discussion of this "myth."

Decanter

- A typically highly decorative, indefinitely re-useable bottle (i.e., a

specialty bottle) made typically for dispensing liquor or wine.

Decanters were usually made from colorless glass, though colored glass is

not uncommon as the image to the right shows. Decanters are

distinguished from a bar bottle by a decanter having a

flanged or flared lip/finish and being sealed with a glass stopper (Ketchum

1975). The decanter pictured to the right is of mid-19th century manufacture and features beautifully colored

glass, a flared finish and a glass stopper. (Photo courtesy of

American Bottle Auctions.) Also see bar bottle.

Decanter

- A typically highly decorative, indefinitely re-useable bottle (i.e., a

specialty bottle) made typically for dispensing liquor or wine.

Decanters were usually made from colorless glass, though colored glass is

not uncommon as the image to the right shows. Decanters are

distinguished from a bar bottle by a decanter having a

flanged or flared lip/finish and being sealed with a glass stopper (Ketchum

1975). The decanter pictured to the right is of mid-19th century manufacture and features beautifully colored

glass, a flared finish and a glass stopper. (Photo courtesy of

American Bottle Auctions.) Also see bar bottle.

Decolorizing

- Decolorizing is in essence neutralizing the effects of the iron and

carbonaceous impurities in the glass mix or batch to obtain

colorless (clear) glass. This is typically done by adding selenium, manganese

dioxide, and/or arsenic

to the batch though there are other methods. Early glassmakers

referred to such substances - particularly manganese - as "glassmakers'

soap" due to the ability of these chemicals to "cleanse" or neutralize the

natural impurities (particularly iron) in the sand used for making glass. See the

colorless glass description on the Bottle/Glass Colors page.

Demijohn

- A larger than usual (several quarts to many gallons) bottle which is typically ovoid

or bladder shaped. See carboy.

Also see the

Carboy/Demijohn section of the "Miscellaneous Bottles" typology page.

Deposition lag

- (aka "time lag") A significant time span between manufacture, use, and discarding

of an item.

Used here in reference to a bottle being thrown away long after it was

manufactured. As an example, it is common to find the fragments

of canning jars manufactured during the mid to late 19th century in dumps or

deposits that date well into the 20th century; the jar only being thrown away when broken after decades of

use.

Devitrification - An alternative term

for the processes and appearance of weathered glass, i.e. "to

deprive of glassy luster and transparency; especially

to change from a vitreous to a

crystalline condition" (Merriam-Webster Online 2009). See

patination.

Dimple

- The small molded depression or hole on the bottle neck into which the lever wire

of a toggle closure device is hooked (White 1978). This is another bottle

feature that is easier to picture than describe - click

dimple to view

a picture of this.

Dip mold - A one (or sometimes 2 or 3) piece bottle mold which forms the base and body of a bottle but

which is open at the shoulder (mold ends). A dip mold also has a slight

narrowing taper from shoulder to

base to facilitate removal of the expanded gather of glass. The body

and base of the bottle are formed in the mold whereas the shoulder, neck,

and finish were formed by blowing and tooling, as in the case of free-blown

bottles. Dip mold bottles often slightly bulge at the shoulder where

the mold ended. Click

dip mold ale to see a close-up picture of a dip mold bottle shoulder.

Click

modern art glass dip molds to see examples of such which - though not

used for bottle production - are identical in form and function to those

used for bottles in the 19th century and before. (Photo courtesy of

Bill Lockhart.) Dip mold bottles almost always date no later than

about 1860 (Deiss 1981). See the dip mold discussion on the

Bottle Bases page. (Note: A type of dip mold was also used

with press-and-blow machines as the parison mold

(Miller & Morin 2004). However, when as used on this website, dip mold

is always in reference to mouth-blown bottles as described above.)

Dip mold - A one (or sometimes 2 or 3) piece bottle mold which forms the base and body of a bottle but

which is open at the shoulder (mold ends). A dip mold also has a slight

narrowing taper from shoulder to

base to facilitate removal of the expanded gather of glass. The body

and base of the bottle are formed in the mold whereas the shoulder, neck,

and finish were formed by blowing and tooling, as in the case of free-blown

bottles. Dip mold bottles often slightly bulge at the shoulder where

the mold ended. Click

dip mold ale to see a close-up picture of a dip mold bottle shoulder.

Click

modern art glass dip molds to see examples of such which - though not

used for bottle production - are identical in form and function to those

used for bottles in the 19th century and before. (Photo courtesy of

Bill Lockhart.) Dip mold bottles almost always date no later than

about 1860 (Deiss 1981). See the dip mold discussion on the

Bottle Bases page. (Note: A type of dip mold was also used

with press-and-blow machines as the parison mold

(Miller & Morin 2004). However, when as used on this website, dip mold

is always in reference to mouth-blown bottles as described above.)

Disk pontil

- This is a variation of the

sand pontil scar which only adhered to the indented bottle base

on the outside edges of the pontil rod head (or the glass gathered onto the

pontil rod head) not to the majority of the pontil rod head/glass gather

area (Van den Bossche 2001). The disk pontil scar typically is a large

circular (or oval, sometimes irregular) scar comprised of small chunks of

glass adhering to the bottle base interspersed with portion that are

essentially chipping of the bottle base where the rod was broken away.

Click

disk pontil close-up to see a disk pontil scar on the base of an

American made figural (pineapple shaped) bitters bottle dating from

the 1850s or early 1860s. This subcategory of pontil scar is somewhat

similar to, but usually much bigger than, the blowpipe pontil scar

which is typically about the size of bottle bore. Users should

reference the

pontil scar or mark portion of the

Bottle Bases page for examples

of the different types and variations of pontil scars, as well as

descriptions of how they were formed.

Disk pontil

- This is a variation of the

sand pontil scar which only adhered to the indented bottle base

on the outside edges of the pontil rod head (or the glass gathered onto the

pontil rod head) not to the majority of the pontil rod head/glass gather

area (Van den Bossche 2001). The disk pontil scar typically is a large

circular (or oval, sometimes irregular) scar comprised of small chunks of

glass adhering to the bottle base interspersed with portion that are

essentially chipping of the bottle base where the rod was broken away.

Click

disk pontil close-up to see a disk pontil scar on the base of an

American made figural (pineapple shaped) bitters bottle dating from

the 1850s or early 1860s. This subcategory of pontil scar is somewhat

similar to, but usually much bigger than, the blowpipe pontil scar

which is typically about the size of bottle bore. Users should

reference the

pontil scar or mark portion of the

Bottle Bases page for examples

of the different types and variations of pontil scars, as well as

descriptions of how they were formed.

Dish base

- A concavity in the base of a bottle which is somewhat shallower than a

push-up or kick-up (White 1978).

Down-tooled

- A term used by Jones & Sullivan (1989) for a "string-rim

profile (which) slopes outward and downward." Those authors used the term

primarily in reference to the appearance of the lower portion of a two-part

finish. A down-tooled finish on an early (1800-1840) American

utility bottle is viewable at this link:

round utility bottle finish. Also see up-tooled.

Druggist bottle

- Also known as pharmacy, apothecary, drugstore, or prescription bottles.

These are a class of bottles used by local druggists to purvey their

products to the public. Most glass companies from the 1870s through he

mid 20th century produced these types of bottles. This category is

covered within this website on the Medicinal/Chemical/Druggist page

at this link:

Druggist/Prescription Bottles.

Duraglas

- This was the proprietary name for a process used by the

Owens-Illinois Glass Company where the surface of the hot, just produced

bottles, were sprayed on the body, shoulder, and neck (not base or the top

of the finish) with a stannic chloride vapor that allowed the tin to bond to

the outer surface and providing scratch resistance and durability to the

bottles. (Information courtesy of Phil Perry, engineer with that

company.) This process - and the embossed notation of it ( in script)

on the base of many Owens-Illinois products - began in 1940 and

continued up until at least the mid-1950s, though the process is still in use

today without the notation (Toulouse 1971; Miller & Morin 2004; Phil Perry, O-I engineer pers. comm. 2007).

The photo to the right (click to enlarge) is of a 1941 beer bottle with the

Duraglas notation in the lower portion of the base embossing.

(See the machine-made bottle dating page

Question #11 for more information on the dating of this bottle.)

Ejection mark

- A ejection mark (also called a valve mark) is a circular mark

left on the base of a bottle or jar as shown in the image to the right

(click to enlarge). It is produced by certain press-and-blow, automatic

and semi-automatic bottle machines (e.g., Lynch MB Two Table) which left this mark when

a more or less centered metal rod pushed

("ejected") the pre-bottle out of the first parison mold so that it could be moved

via the grasping ring mold (a separate part of the

parison mold) to the second and final blow mold (Tooley 1953).

Ejection marks

are virtually always found just on milk bottles, rarely on soda bottles made from the

early 1900s into the 1940s. Also see valve mark below

for a discussion of an identical marking found on wide mouth/bore bottles

also produced on different press-and-blow machines. See the description

of ejection marks on the

Bottle Bases page for more information. Both ejection and

valve markings are an indicator that the bottle/jar was produced on some

type of press-and-blow machine.

Ejection mark

- A ejection mark (also called a valve mark) is a circular mark

left on the base of a bottle or jar as shown in the image to the right

(click to enlarge). It is produced by certain press-and-blow, automatic

and semi-automatic bottle machines (e.g., Lynch MB Two Table) which left this mark when

a more or less centered metal rod pushed

("ejected") the pre-bottle out of the first parison mold so that it could be moved

via the grasping ring mold (a separate part of the

parison mold) to the second and final blow mold (Tooley 1953).

Ejection marks

are virtually always found just on milk bottles, rarely on soda bottles made from the

early 1900s into the 1940s. Also see valve mark below

for a discussion of an identical marking found on wide mouth/bore bottles

also produced on different press-and-blow machines. See the description

of ejection marks on the

Bottle Bases page for more information. Both ejection and

valve markings are an indicator that the bottle/jar was produced on some

type of press-and-blow machine.

Embossing -

Raised lettering, designs, or graphics on the surface of the bottle that are

formed by incising on the mold surface(s). The image to the left shows

distinct embossing on a Hutchinson style soda bottle dating

from the first years of the 20th century. Also see plate below. See the

General Bottle Morphology page for an illustration and the

Bottle Body Characteristics & Mold Seams

page for more information on embossing.

Embossing -

Raised lettering, designs, or graphics on the surface of the bottle that are

formed by incising on the mold surface(s). The image to the left shows

distinct embossing on a Hutchinson style soda bottle dating

from the first years of the 20th century. Also see plate below. See the

General Bottle Morphology page for an illustration and the

Bottle Body Characteristics & Mold Seams

page for more information on embossing.

Empontilling - The

process of attaching a typically iron rod (pontil) to the base

of a bottle (and other glass objects) to secure it while the neck and finish

were being completed (i.e., finishing). See pontil mark or scar below.

Feeder machine - A generic name for

gob feeder enabled automatic machines which were

semi-automatic machines made fully automatic with the incorporation of a

glass supply or feeding device and a blank transfer mechanism (Pearson 1928).

Fifth

- Collector jargon term for a 1/5th (approximate) gallon capacity cylinder

liquor bottle which is relatively tall and narrow with straight (vertical)

sides. This is shape which is

still widely used today for spirits of all kinds. Click

SF&PGW fifth for picture of a Western American made "fifth" dating from about

1880.

Figured flask - A generic name for

the large class of liquor flasks primarily produced between 1815 and 1870

which are also referred to as "historical", "pictorial", or "decorative"

flasks. These flasks were quite popular during that era because they were

both functional and decorative (McKearin & Wilson 1978). The image

to the right is of a "sunburst" design, early American, figured flask

produced in New England (Keene, NH.) about 1815-1817. This flask is

discussed more on the

Liquor/Spirits Bottles

page.

Figured flask - A generic name for

the large class of liquor flasks primarily produced between 1815 and 1870

which are also referred to as "historical", "pictorial", or "decorative"

flasks. These flasks were quite popular during that era because they were

both functional and decorative (McKearin & Wilson 1978). The image

to the right is of a "sunburst" design, early American, figured flask

produced in New England (Keene, NH.) about 1815-1817. This flask is

discussed more on the

Liquor/Spirits Bottles

page.

Figural bottle

- A bottle molded in the shape of things - animal (including humans),

vegetable, and mineral (Munsey 1970). For an example of a Civil War

era bitters or liquor bottle in the shape of a pineapple, click

pineapple figural bottle.

Filamented ring

- A ring on the base of early

machine-made bottles formed when the gob of glass was severed after being

drawn into the mold (White 1978). Also called a

suction scar . The filamented ring may be more a reference to

the versions of this mark where the cut was "sloppy" like the in the pictured

bottle in the description of the suction scar below.

Finial

- The upper portion of a glass stopper which grasped to remove it from the

bottle. Also used to refer to the "decorative, terminal part of an

object" (Kaiser 2009) like the decorative curl at the end of an applied

handle on a bottle.

Finish

- Simply put, the finish is

typically everything above the distinctive upper terminus of the neck.

It refers to the combination of the lip (upper part) and collar

(lower part) of a finish, if both are present, or any other distinct parts

if present. The term

"finish"

originates as a

reference to the final process of making a mouth-blown bottle - completion or

"finishing" of the lip and upper portion of the neck.

Generically, a finish can have one-part, two-parts (the crown finish to the

above right is two-part), three-parts, and rarely more parts (Jones &

Sullivan 1989). The finish on a bottle is also referred to sometimes

as a "top," "mouth," or "corkage" (U. S.

Patent Office 1893; Howard 1950; White

1978). (Note: Semi-automatic and fully-automatic bottle machines start the bottle manufacturing

process with the finish/lip but the term is used for all bottles -

mouth-blown and machine-made. On ground

finish, external screw thread bottles the actual "finishing" part

of the manufacturing process is the grinding of the top surface of the

finish rim, as the threads were

formed by the mold itself.) The image to the left shows five different

finishes spanning the time frame from the 1850s to 1920s. See the

Bottle Finishes page for much more information on finishes.

Also see the

General Bottle Morphology page for an illustration.

Finish

- Simply put, the finish is

typically everything above the distinctive upper terminus of the neck.

It refers to the combination of the lip (upper part) and collar

(lower part) of a finish, if both are present, or any other distinct parts

if present. The term

"finish"

originates as a

reference to the final process of making a mouth-blown bottle - completion or

"finishing" of the lip and upper portion of the neck.

Generically, a finish can have one-part, two-parts (the crown finish to the

above right is two-part), three-parts, and rarely more parts (Jones &

Sullivan 1989). The finish on a bottle is also referred to sometimes

as a "top," "mouth," or "corkage" (U. S.

Patent Office 1893; Howard 1950; White

1978). (Note: Semi-automatic and fully-automatic bottle machines start the bottle manufacturing

process with the finish/lip but the term is used for all bottles -

mouth-blown and machine-made. On ground

finish, external screw thread bottles the actual "finishing" part

of the manufacturing process is the grinding of the top surface of the

finish rim, as the threads were

formed by the mold itself.) The image to the left shows five different

finishes spanning the time frame from the 1850s to 1920s. See the

Bottle Finishes page for much more information on finishes.

Also see the

General Bottle Morphology page for an illustration.

Finishing

- The last step in the process of producing a mouth-blown bottle - the development

or "finishing" of the

end of the neck where the blowpipe was removed (i.e., forming a lip).

Also called "goffering" during the 19th century (U. S. Patent Office

1886).

NOTE: The author of this website has prepared a summary of the mouth-blown bottle finishing methods section on the Bottle Finishes & Closures page which is available as a downloadable and printable (pdf) article entitled: "The Finishing Touch: A Primer on Mouth-blown Bottle Finishing Methods with an Emphasis on "Applied" vs. "Tooled" Finish Manufacturing."

Finishing mold - See blow mold.

Finishing tool - See

lipping tool.

Fire grenade

- A type of bottle designed to be filled with carbon tetrachloride (a fire

retardant) and thrown into fires to extinguish them; an early "fire

extinguisher." These type bottles were fairly common from about 1880

to well into the 1900s, when vaporized chemical fire extinguishers were

invented and found to be much more useful and efficient (Munsey 1970).

One of the more common, late 19th century fire grenades is pictured to the

right - the HARDEN'S HAND GRENADE. For more information on the

subject see the Miscellaneous &

Foreign Bottles typology page.

Fire grenade

- A type of bottle designed to be filled with carbon tetrachloride (a fire

retardant) and thrown into fires to extinguish them; an early "fire

extinguisher." These type bottles were fairly common from about 1880

to well into the 1900s, when vaporized chemical fire extinguishers were

invented and found to be much more useful and efficient (Munsey 1970).

One of the more common, late 19th century fire grenades is pictured to the

right - the HARDEN'S HAND GRENADE. For more information on the

subject see the Miscellaneous &

Foreign Bottles typology page.

Fire polishing

- The reheating of a bottle or portion of a bottle (like a sheared lip or

neck) in the glory hole to remove tooling or mold marks and/or obtain a smooth surface.

Usually gives the glass surface a almost liquid like sheen. Commonly done as part of the finishing process during the first half of the

19th century on pictorial or figured flasks. The body of the clear

green sunburst flask

pictured above to the right was fire polished. Also see the picture near the

sheared

finish or lip description

below which is a close-up of the same flask. It should be noted that

this was also done on the finishes of early (first half of the 20th century)

machine-made bottles to smooth out the neck ring mold seams on the finish

rim for better sealing by rim sealing closures - particularly screw caps and

on the

crown cap finish (Lockhart et al. 2009b).

Flared finish

- A finish or lip that spreads outward so as to create an opening whose opening is

wider at the top than any other point on the neck (White 1978). A

flared-sheared finish as described by White is pictured to the right.

A

flare finish is also a type of finish covered on the Bottle Finish

Types & Styles page. The term is also used to describe a bottle finish which protrudes ("flares")

away the neck horizontally more than its vertical depth or thickness.

Click flared

finish to see a picture of this

alternate type flared finish which is

relatively common on medicinal bottles from the mid-19th century

through early 20th century.

Flashing

- Also called "flashed," "striking" or "cased glass" by glassmakers (Tooley 1953;

Kaiser 2009);

also see casing. A term for glassware or bottles with a thin layer of opaque or colored

glass overlaying a colorless (aka "clear") glass body, or vice versa

(clear over colored glass). This is done by various means

including applying a thin layer of glass over the main body glass

(possibly by dipping?). The process of "striking" - which could

also result in the same effect - is more chemical and heat induced.

According to Kulasiewicz (1974), "..the striking process is

complicated and often depends on special heat treatments to start the

crystallization process and special chemicals to reduce the metal out of

the melt or to act as the nuclei for growth." That author also

notes that "...complicated theories have been published, yet

these do not dispel the magic of clear glass suddenly becoming colored."

Flashing was little used with utilitarian bottles but was

commonly used on glassware and specialty bottles.

Flask

- A bottle originally designed to be portable and easy to carry, which is

typically oval or rectangular in cross-section and laterally compressed on

two sides. Though the shape can be found in a multitude of sizes, on

this website flasks are considered to have a capacity of about 16 oz. or

less which is a more or less the upper limit of a "portable" size. Two

sizes (pint and half-pint) of the "Eagle" style flasks are pictured to the

left; this style is discussed on the

Liquor/Spirits Bottles

page.

Flask

- A bottle originally designed to be portable and easy to carry, which is

typically oval or rectangular in cross-section and laterally compressed on

two sides. Though the shape can be found in a multitude of sizes, on

this website flasks are considered to have a capacity of about 16 oz. or

less which is a more or less the upper limit of a "portable" size. Two

sizes (pint and half-pint) of the "Eagle" style flasks are pictured to the

left; this style is discussed on the

Liquor/Spirits Bottles

page.

Flint glass

- A heavy, leaded glass of high quality with high refractive power, and

great luster used in the choicest cut glassware (White 1978). It was

also glass made using calcined flints, or flints reduced to a white

powder, as a source of silica (Kaiser 2009). The term

later used loosely by glass manufacturers in reference to clear or

colorless glass in

general (Scholes 1941).

Flux

- A substance - usually soda - which promotes the fusion of glass.

Free-blown

- Glass formed by blowing and manipulation by hand and/or with tools but

without the aid of a mold to shape the bottle. Thus, a free-blown bottle has no

mold seams or other mold induced markings. Also called "off-hand"

blowing or working (Scholes 1952).

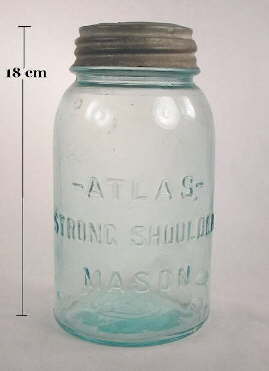

Fruit jar

- Glass jar in which food is preserved at home, typically having a wide

mouth for access. The pale aqua quart jar pictured to the right is an

example of a fruit jar that dates from the 1920s (Creswick 1987). See

canning jar which is the preferred term on this website since it is

more embracing, though both terms may be used interchangeably.

Fruit jar

- Glass jar in which food is preserved at home, typically having a wide

mouth for access. The pale aqua quart jar pictured to the right is an

example of a fruit jar that dates from the 1920s (Creswick 1987). See

canning jar which is the preferred term on this website since it is

more embracing, though both terms may be used interchangeably.

Full sized bottle mold

- A bottle mold that is used to form a specific shape and size of bottle

where the interior surface of the mold is the same size as the outside of a

finished bottle. An inflated gather is placed into a

full sized mold and expanded until the outside surface of the gather